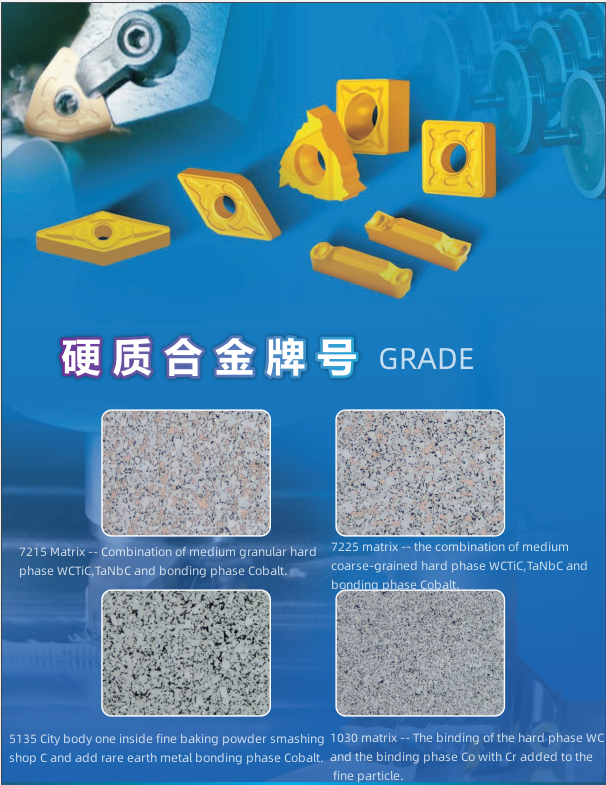

I-RPMT RDMW1204MO Indexable Milling Insert Carbide Ifaka I-Lathe Tools Face Milling Cutter

Isingeniso Sebanga Lokubalulekile

Isingeniso sesethulo sezinto eziguqukayo:

I-7215 inamandla aphezulu kanye nokuqina kwe-matrix yokumelana nobuthi obuphezulu, kuhlanganisiwe

nge-MT-TICN, AL2O3,TIN inhlanganisela enhle kakhulu yenqubo yokuhlanganisa, bese

ngokusebenzisa i-coating ethuthukisiwe ngemuva kokwelashwa ukuze kuqedwe ukucindezeleka kwangaphakathi kwe-blade layer, efanelekile ekuqedeni insimbi evamile.

I-7125 enqenqemeni yokuphepha yamandla aphezulu, ukuqina okuphezulu kwe-matrix ehlanganiswe ne-MT-TICN kanye nenqubo yokuhlanganisa i-superfriction AL203, bese ngenqubo yokwemboza ethuthukisiwe yangemva kokwelashwa ukuze kuqedwe ukucindezeleka kwangaphakathi kwe-coating, elungele ukucutshungulwa kwensimbi okujwayelekile, ukuqedwa kancane kanye ingxenye yezidingo zobuhwaba bomsebenzi awukona ukuqeda okuphezulu.

I-4025 ukumelana nokugqwala okuphezulu, nangenqubo ethile yokufaka ingcindezi ye-matrix yamandla aphezulu kanye ne-MT-TICN kanye nenhlanganisela enhle kakhulu ye-AL2O3 ewugqinsi, enobuchwepheshe obuphambili bokunamathela ngemuva kokwelashwa ukuze kutholwe indawo yokunamathela ebushelelezi, elungele umshini onzima, ukuqeda kancane. kanye nokuqedwa kwensimbi eyinsimbi.

1030 okusanhlamvu okuhle, ukumelana okuhle kakhulu kokuguqulwa kanye nenqubo ye-sintering yokucindezela ukuze uthole amandla aphezulu aphezulu kanye ne-matrix yokumelana nokugqoka, ngenqubo yokuhlanganisa i-nano PVD, bese ngokusebenzisa i-coating ethuthukisiwe ngemva kokwelashwa ukuze kutholwe indawo enamathelayo ebushelelezi, efanelekayo ukuqedela insimbi evamile, insimbi ecinyiwe, insimbi ecwecwe nge-chromium nensimbi engagqwali ukuqeda nokuqeda.

1120 okusanhlamvu okuhle kakhulu, ukumelana okuhle kakhulu kokuguquguquka, nangenqubo ye-sintering yokucindezela ukuze uthole amandla aphezulu kanye ne-matrix yokumelana nokugqoka, ene-nano SI equkethe inqubo ye-PVD yokuhlanganisa, ngemva kokwelashwa okuthuthukisiwe kwangemuva kokwelashwa ukuze kutholwe indawo yokunamathela ebushelelezi.Ifanele i-grooving kanye nokusikwa kwensimbi evamile, insimbi eqinile nensimbi ephonsiwe.

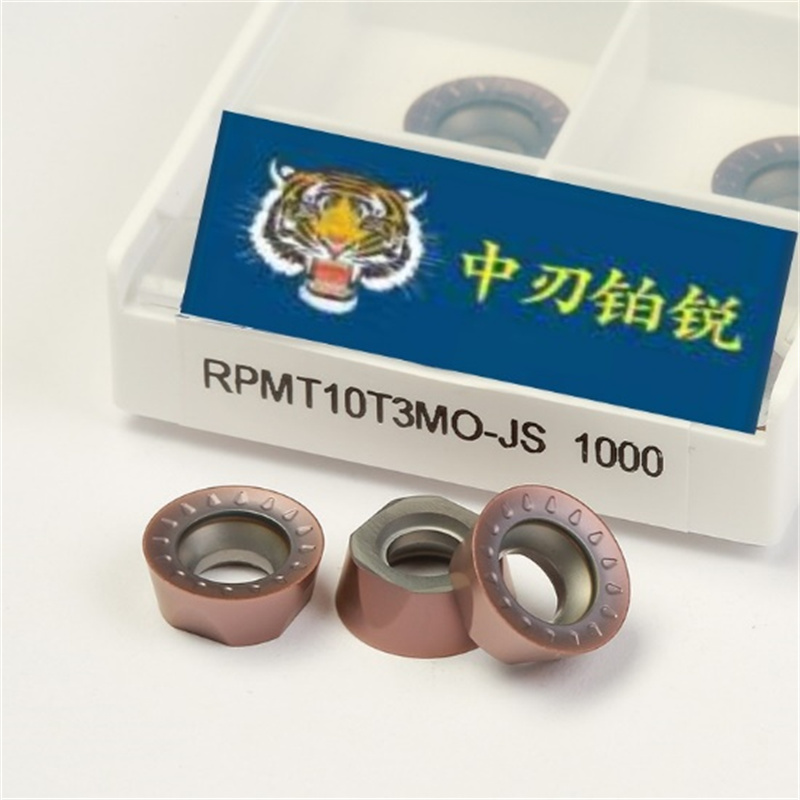

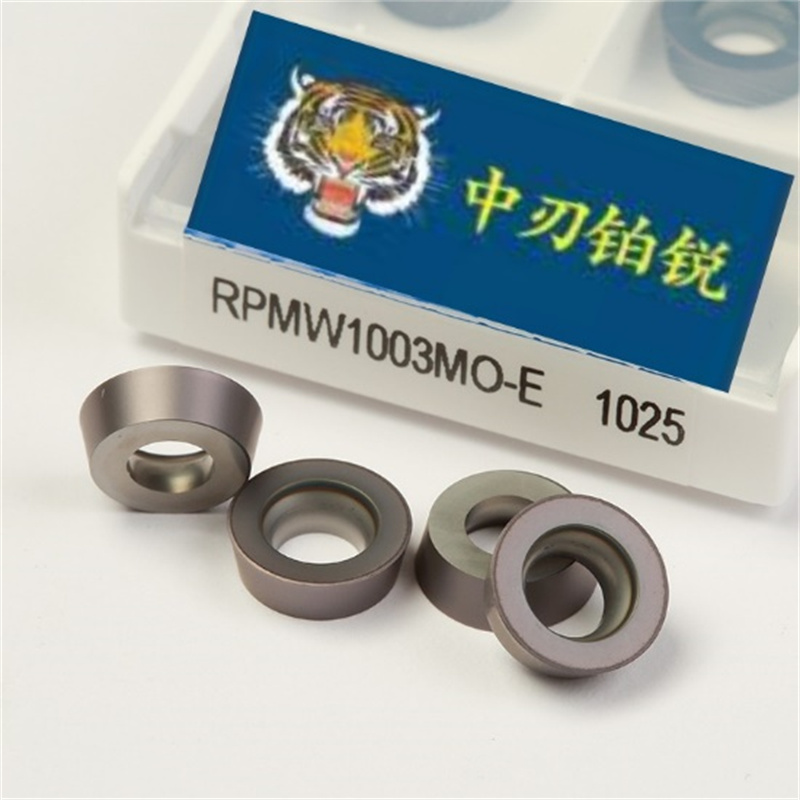

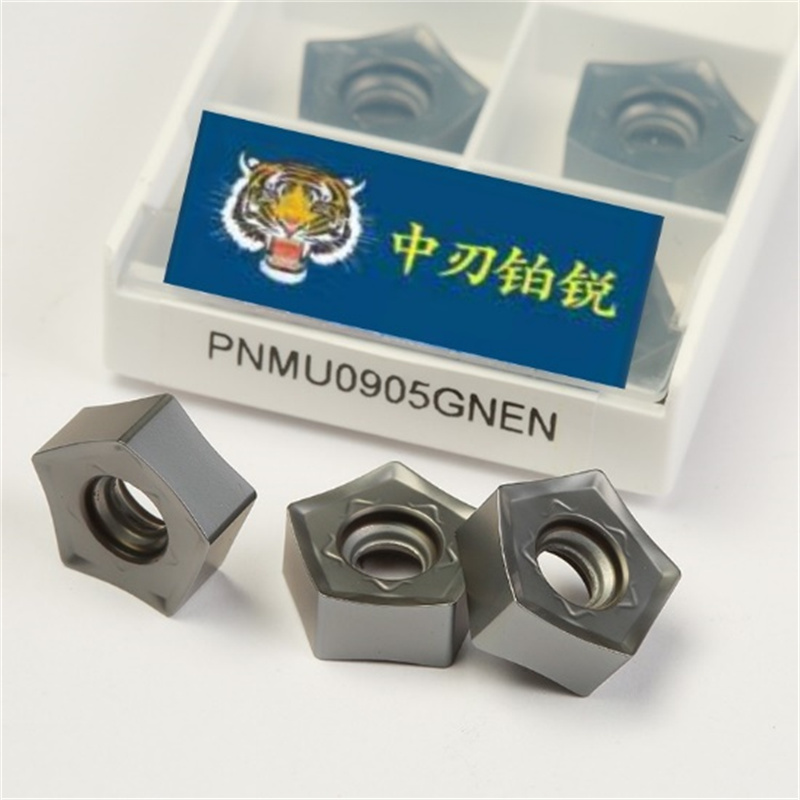

Ukwethulwa kwezinto zokugaya nokugaya

I-1030 NC-TIALN inamathela ehlanganiswe ne-matrix eqinile ne-ductile yezinhlayiya ezinhle ifanele ukugaya okumahhadla nokuqedwa kokuqedwa kwazo zonke izinhlobo zezinto ezicutshunguliwe.I-grooving, ukusika kanye nokubhoboza i-half aperture.

I-1130 NC-TIALN yokugqoka equkethe i-SI ihlanganiswe nezinhlayiya ezinhle kanye nokuqina okuhle kwe-hard alloy matrix, ifanele insimbi engagqwali, isigaba sensimbi esakhiwe kanye ne-semi-finish ukuze icutshungulwe, ukufeza inhlanganisela ephelele yokuphepha nokumelana nokugqoka.

I-5035 eyengeziwe yokugqoka kanye nezakhi zokumelana nokushisa okuphezulu kwe-CVD enamathela, ubulukhuni obuphezulu bokunamathela kanye nokumelana nokushisa okuphezulu kakhulu ukunikeza ukuvikelwa okuphumelelayo konqenqema lokusika, ubuchwepheshe bokwelapha obukhethekile bokuhlanganisa, ukugqoka kanye ne-matrix ngokuqinile, ifanelekela ingxube yokushisa ephezulu, i-titanium alloy materials ngokunemba. ukucubungula ukugaya.

I-5135 NC-TIALN inamathela equkethe i-SI ehlanganiswe ne-carbide matrix enokuqina okuhle kakhulu komthelela, ifanele izingxenye zensimbi, insimbi engagqwali, i-grooving, ukusika ukusika okujulile, ukucutshungulwa kokuphakelayo okusheshayo kanye nokucutshungulwa kokumba kwembobo enkulu.

Isicelo

Isicelo Esiyinhloko:Ngokucubungula insimbi ye-carbon, insimbi ekhonjiwe, insimbi engagqwali

Kubulukhuni obuhlukene bezinto zokusebenza zesikhunta, singahlola impilo yamathuluzi okusika ngokunembile.Ubungcweti bokugaya insimbi noma insimbi engagqwali noma ukugaya okusansimbi noma ingxubevange ye-aluminium, izinsimbi zethu zokugaya zenziwe ngendlela ehlukile ngekhwalithi yomhlabathi ye-ultra-fine carbide, kanye nobuchwepheshe bokunamathela be-AlTiN obuphezulu be-Al.Lokhu kwenza i-Milling cutter yethu ibe nomphumela okahle wokucubungula kanye nekhwalithi ezinzile ukuya phezulu.

Imininingwane Yomkhiqizo

| Uhlobo | Ubukhulu(mm) | ||

| D | S | D1 | |

| RDMW120400-PR | 12.00 | 4.76 | 4.40 |

| RDMW1204MOT-PM | 12.00 | 4.76 | 4.40 |

| Idatha ye-RDMW1204MO-TT | 12.00 | 4.76 | 4.40 |

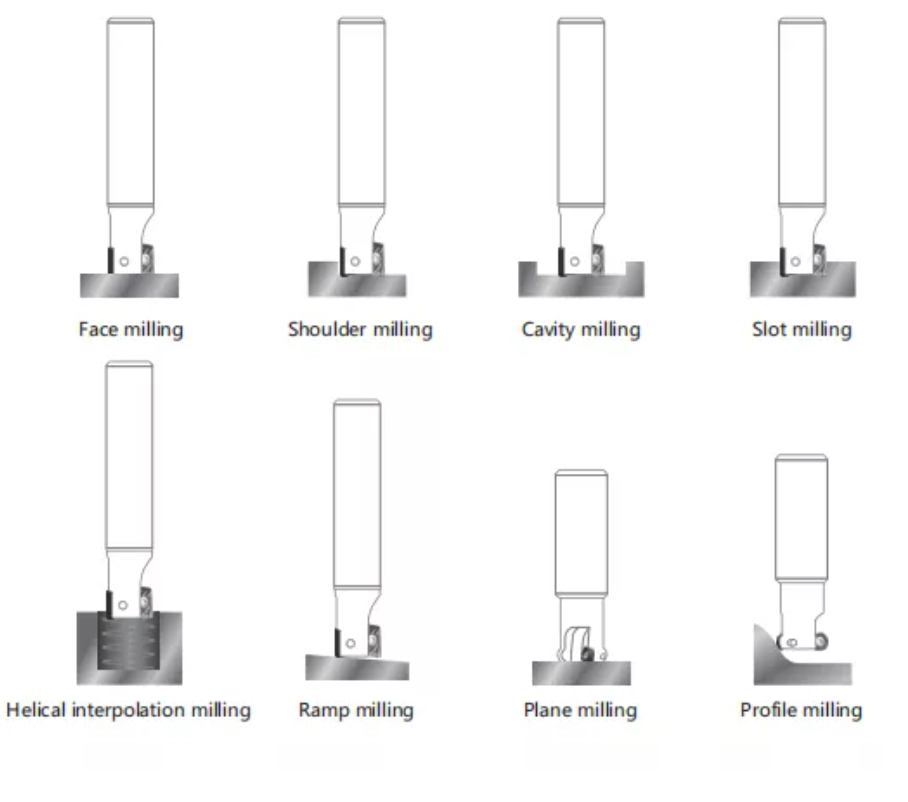

Kungakhathaliseki ukuthi udinga umshini ojwayelekile wokugaya noma izinto ezisindayo zokugaya ubuso, ukugaya ihlombe, ukugaya i-slot, ukugaya iphrofayili, noma ukugaya i-ramp, noma ngisho nezidingo eziphakeme zokugaya ubushelelezi bendawo, Unjiniyela wethu angaguqula idizayini yakho ifake isigayo ngezinsuku nje.

Isibonisi sokumboza

Izitifiketi

Izinsiza Zokukhiqiza

Imishini ye-QC

Inkonzo Yethu

Isevisi yokuthengisa ngaphambilini:

Sinabasebenzi bokuthengisa abangochwepheshe, abangakwazi ukwazi imininingwane ngezidingo zakho futhi banikeze impendulo.

Isevisi yokuthengisa:

Ngemuva kokusayinwa kwenkontileka, abasebenzi bethu abangochwepheshe bazoxhumana futhi basebenze ngamashejuli okukhiqiza noma ushintsho lwesidingo sakho.

Isevisi yangemuva kokuthengisa:

Sizohlela ukubuyiselwa nokushintshwa kwemikhiqizo ngesikhathi uma inezinkinga zekhwalithi.Ngesikhathi esifanayo, izimpindelo zizokwenziwa njalo ukuze wazi isimo sesevisi yemikhiqizo yethu.